Friday, Bayou Cajun Homeschoolers took a tour of the The Advocate production facility. Due to the age restrictions, this was our older kid field trips for this quarter. You had to be at least 9 years old to tour the facilities.

The Advocate is our local newspaper. It is one of the few family owned newspapers in the country. Most of them are owned by very large corporations. This location is where the newspaper gets printed. They have another location where the majority of the employees work including the reporters and designers. Everything is sent for printing via the internet.

I scheduled two different tours to accommodate more of our children since you could only have 12-15 people total on the tour. The second group will be going in June.

Group 1

Ms. Charlene gave us a tour of the facility. She was very informative and welcomed any question that we wanted to ask. When you walk into the building you will see this old, large printing reel. This is what they used before the computer technology. There is also a security area so you are not allowed past this area without clearance.

You can see the old metal plates that were used for printing. They were heavy and had raised type on them. Each one of these plates were saved from important front page news. You can see the one when we dropped the atomic bomb on Japan.

After an overview of the process and the discussion regarding the old technology versus the new technology, we headed back to the back of the building and toured the facility in order of the printing process.

This is the recycle area where all of the messed up paper goes to be recycled.

The big vats of ink used for printing

The first picture shows where the paper has to sit to get acclimated to the temperature before it can be used. First, it sits there with the paper covering. Then, the brown paper is removed for more acclimation.

The second picture shows what they do when the paper is unusable. As each batch of paper rolls gets delivered, they mark it with the date of delivery and the number of rolls in that batch. This allows them to pull all of the defective paper and return it for a refund.

In the reel room, the paper is feed through the machines for printing at the bottom of the machine. When the rolls get to a certain level, they are discarded.

These weights were sitting on the floor by the machines. Ms. Charlene wasn’t really sure why they were there except that the workers may use them to workout in their spare time;) She said back in the day when you use the old reels, you didn’t need to work our.

5 of the different size paper that is used

When you go up to the next level, you can see the newspaper being printed….ink onto the paper.

You can see some of the images on the reels that are being printed on the paper that day. They were printing part of the Sunday paper while we were there. Many things are printed days in advance especially for the large Sunday paper except for the important news stories (things that can change at the last minute) which is printed in the middle of the night for the next day.

The quiet room

This room is more quiet than the other rooms that are printing. Here people are looking at computers and the machines to ensure that there are no technical difficulties and that everything is running smoothly.

This is where the plates for each page of the newspaper are created. The images and type are transferred onto thin metal plates.

The new style plates that are used for printing. There is low light in this area due to exposure issues that you would have in a film developing room. It is made so the ink is absorbed in just the right spots on the plates. These plates are smooth unlike the raised type on the old metal plates. Also, these plates are recycled.

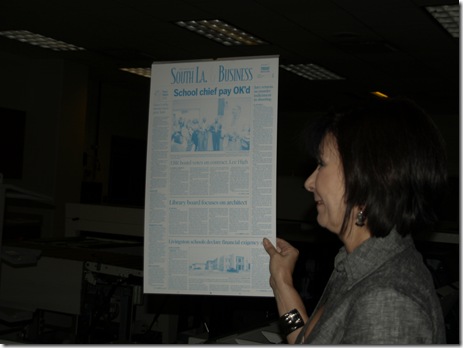

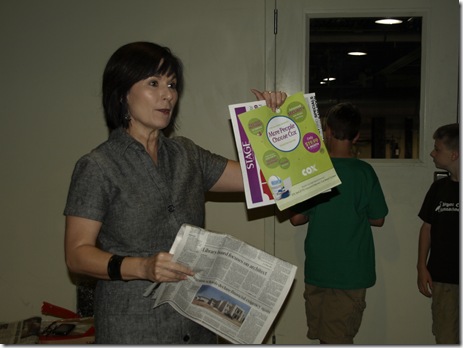

Ms. Charlene is showing us the preprinted ads that are sent to them to insert in the paper. The ads you see with slick, shiny paper are not printed here. They can only print on the special paper which is not shiny. All of this is getting us ready to walk into the packaging area of the facility.

The packaging room

This is wherer the papers are being stuffed with ads and extras along with getting prepared for being shipped out for distribution.

Watching the machines in action and explanation of the process

Watching the shrink wrap being applied to the ready crate.

Storage area

This is where parts of the paper are stored until it is all printed and put together for distribution. Each crate is labeled for the area where it will be delivered or dropped off at the different distribution centers.

The tour lasted about 2 hours. It was very informative in the entire process of making and printing the newspaper. We are very thankful for companies like these who give our children opportunities to learn about different industries and how they function.